FLOCA (Fill Liquid Optical Clear Adhesive)

FLOCA(Fill Liquid Optical Clear Adhesive):Optical bonding it a technique which is used to laminate touch screens or cover glass to display, special glue and a unique manufacturer’s technology are required for the entire operation

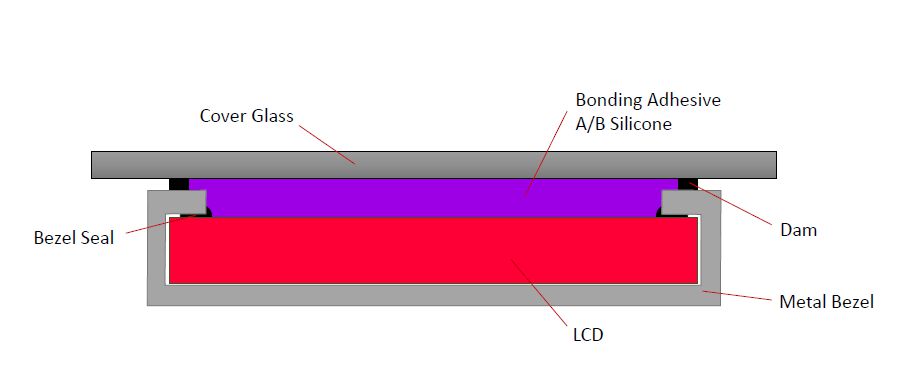

Optical Bonding Setup

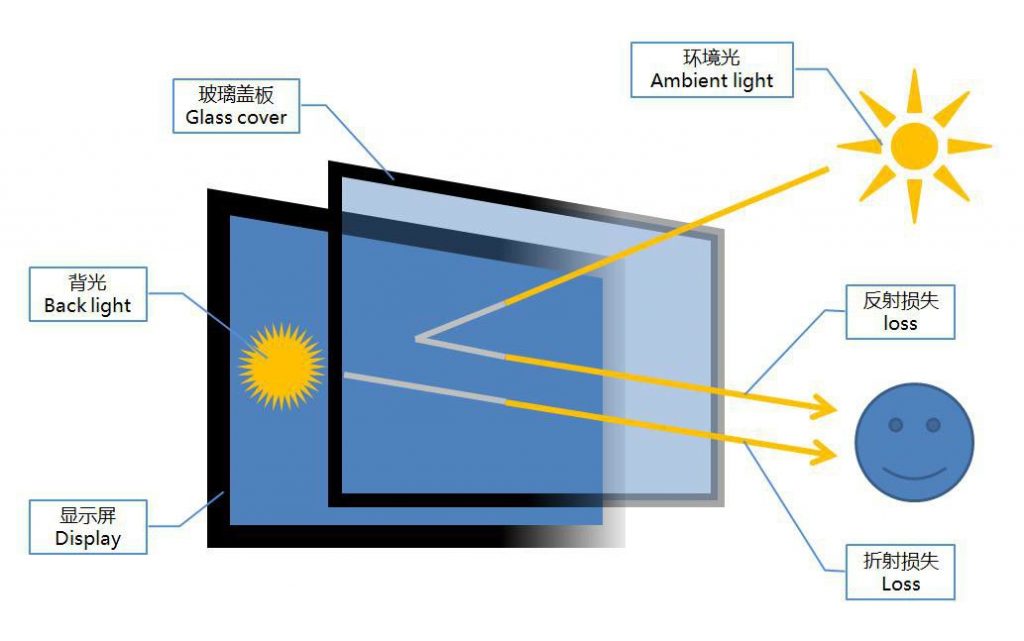

The advantages of optical bonding

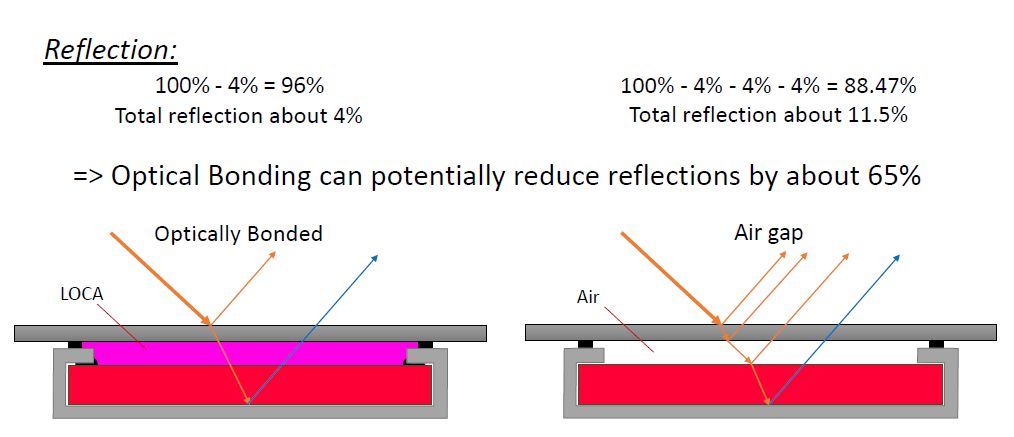

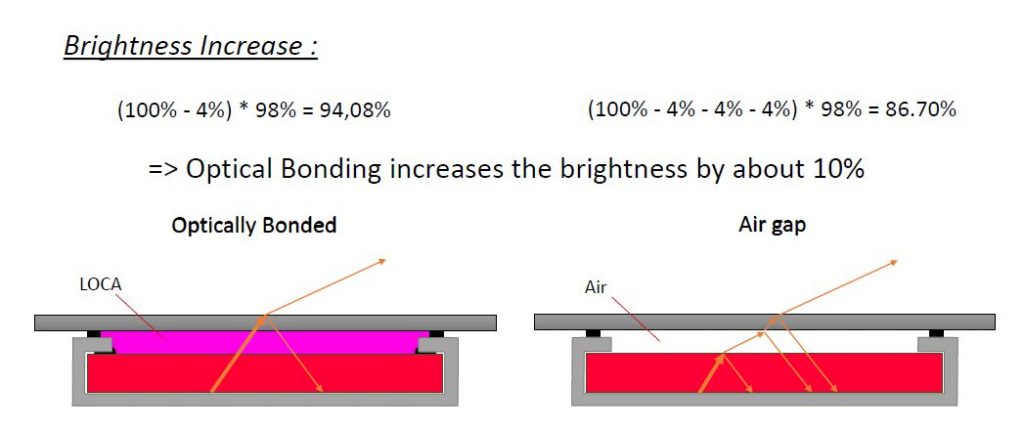

Increase the brightness up to 10%

The adhesive used in optical bonding reduces the refraction effect, as

the refractive index of the adhesive is similar to glass Reduced reflections up to 65% and refractions

Increase the brightness up to 10%

By bonding the LCD module and glass together it removes the interruptions and chances for the light to be reflected back. More light gets through to the surface of the cover glass

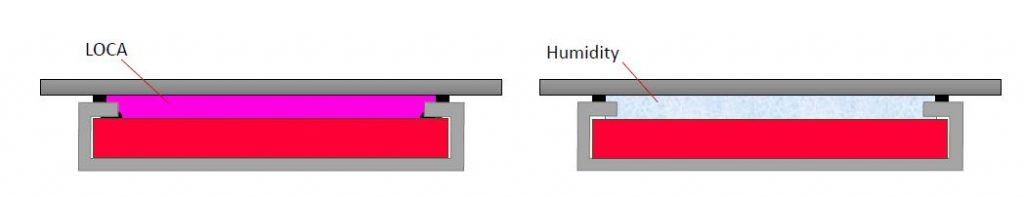

Prevents from Humidity, Condensation and Dust

The most obvious benefit to adding a resin bonding layer between the glass and LCD module is that it physically prevents dust and liquid ingress from getting between the two.

Optical bonding should therefore be considered for any outdoor application as well as indoor applications e.g. production halls and warehouses, in hospitals.

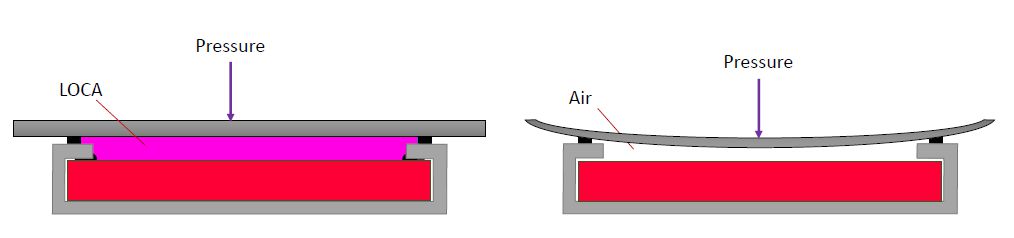

Ruggedizing:

Filling the air gap with silicone gives additional strength to environmental forces which otherwise could brake the glass. At the same time the silicones elasticity is still sufficiently to absorb shocks.

The advantage of silicone optical bonding compare with Acrylic

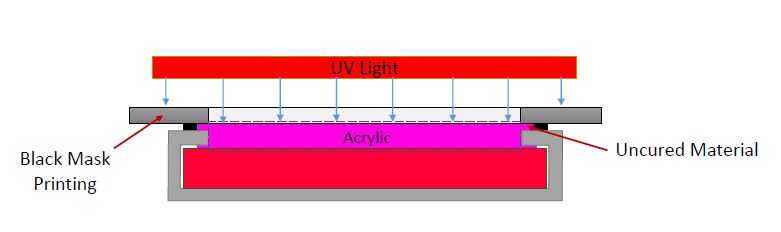

Control curing process

Using UV light to cure acrylics, the processing happens very fast, the areas won’t cure if it didn’t get illuminated, so there may have uncured acrylics remaining underneath of the black mask printing. On the opposite, the silicones cure as soon as two components got mixed, the reaction is relatively slow. It can accelerate the temperature during the process, enable the silicones cure evenly.

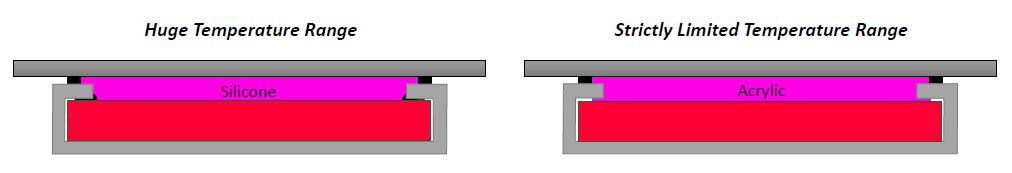

Better temperature range:

Acrylic material require an operating temperature range of only -30 to +80°C and medium-term Yellowing While silicone, which the silicone with features an operating temperature range of -40 to + 120°C and shows stable performance. If at extremely low temperatures (below -40 °C) the material just crystallizes which is completely reversible. But acrylics get irreversibly degenerated if at their specified temperature ranges.

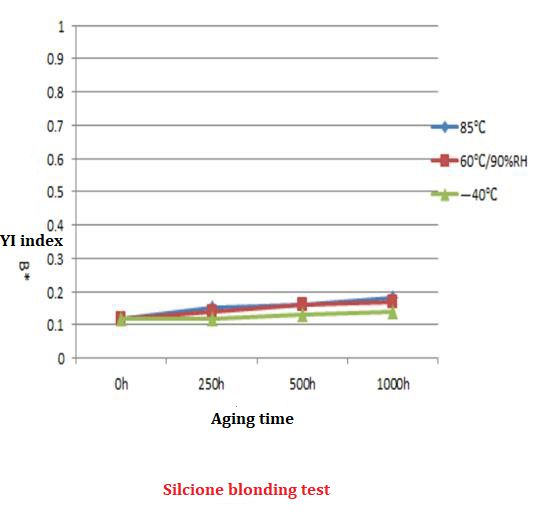

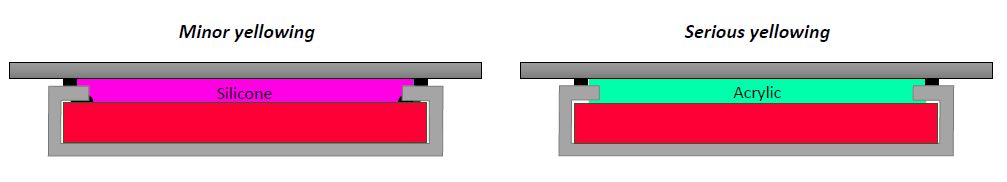

Low yellowing fill material:

The UV catalyst which used in Acrylics bonding is very sensitive to UV light and shows high tendency of yellowing. the screen readability turn down after using outdoor for a period.The additive curing method of temperature as well as UV curing silicones is very stable against UV light and shows a very minor yellowing effect only.

Rework-able:

Can rework the bonding processing at room temperature if occur defective such as air bubble, foreign matter while without effect the TP and LCM, increasing the yield rate

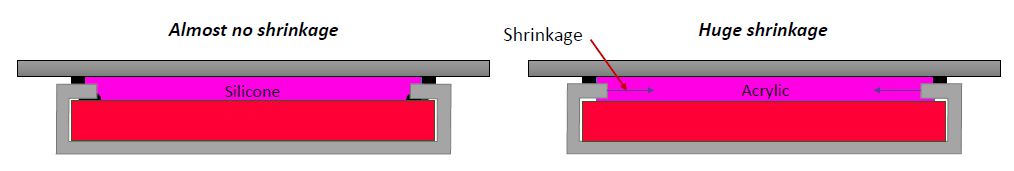

Very low curing shrinkage:

All adhesive experience some shrinkage during cure, the shrinkage rate of silicone is below 0.1% whereas acrylic shrinkage is about 4%, the higher shrinkage cause the mechanical forces on the display which can cause bright spots as well as discolorations.

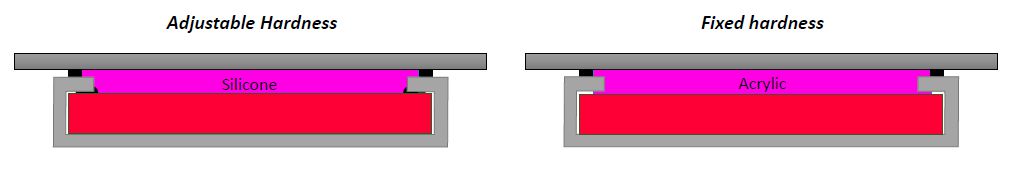

Hardness adjustable:

Some products may require a different material hardness than others, the hardness of acrylics is predefined which is impossible to change, but silicones is a simple variation of the mixing ratio that can change the materials hardness in a wide range

Comparison between optical bonding (right) and without bonding (left)